Flex ECO Features

| Advanced Controls The Flex ECO system utilizes dual advanced microprocessor controls with 32bit CRC and Hamming Code, providing ultra fast, safe, precise and error-free encoding and decoding. Over One Million Unique ID Codes Each and every Flex ECO system has its own unique ID codes, never repeats. Receiver Status Feedback The Flex ECO system is capable of two-way communication between the transmitter and receiver and as well as receiver to receiver with status feedbacks (e.g. receiver MAIN relays and fault detection). |

|

|

62 User Programmable Channels Advanced synthesized RF controls with 62 built-in channels set via pushbuttons and dipswitches. When the transmitter channel is changed the receiver channel is also changed accordingly. Wireless Remote Pairing Function System information can be transferred wirelessly between two transmitters or between a transmitter and a receiver without the hassle of resetting the spares. Reliable Pushbuttons The transmitter pushbuttons are ultra durable and reliable for more than one million press cycles. |

| Ultra Durable & Rugged Enclosures The transmitter and receiver enclosures are made from industrial strength nylon and fiberglass composite material, not ABS plastic. All housings meet the IP66/NEMA4 requirements and are highly resistant to dirt, liquid, acid, alkali, grease and oil penetration. The receiver enclosures and output cables are UL94-V0 rated. Compact and Lightweight The ergonomically designed transmitter and receiver enclosures are extremely compact and lightweight for easy operation and installation. |

|

|

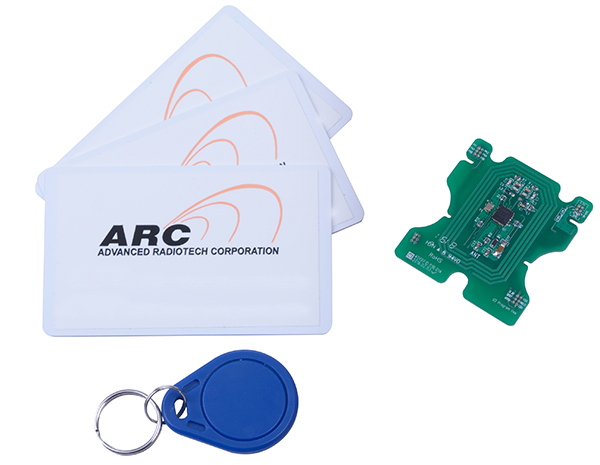

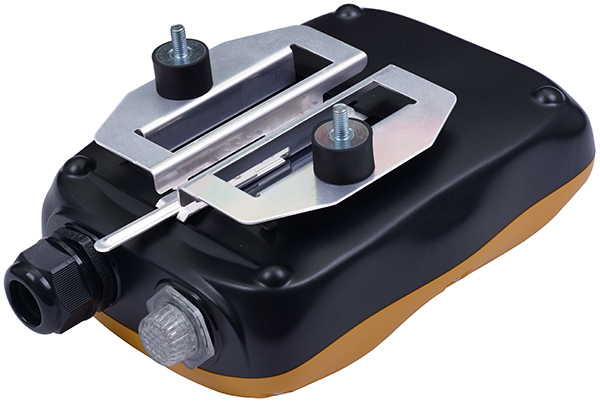

Unique Mounting Bracket The removable receiver mounting brackets are uniquely designed for easy mounting and dismounting. Programmable Transmitter Access Card (TAC) The optional transmitter access card feature (TAC) further guard against any unauthorized personnel from operating the system. The TAC can also be individually programmed unlocking any specific function or functions on the transmitter allowing a more experienced or qualified user to operate, such as the magnet lift, tandem operation, entering restricted areas, etc... The TAC is based on the RFID technology so any industry standard RFID cards or chips can be programmed into the transmitter, such as the commonly used employee RFID badges. |

| Low Power Consumption The transmitter requires only two "AA" alkaline batteries with more than 150 hours of operation. If rechargeable method is preferred, any off-the-shelf high capacity Ni-MH rechargeable batteries can be used in conjunction with the in-house designed charging station, fully interchangeable. Abundant Programmable Functions All functions and settings are easily set via pushbuttons, dipswitches, jumpers, and in-house designed programmer unit. Customized functions can also be added upon request. |

|

|

Full System Compatibility The software and hardware are fully compatible regardless of model type, minimizing spare parts inventory. Prewired Output Cable A prewired cable is standard equipment on all Flex ECO systems. |

| Pitch & Catch Operation This standard-equipped function allows two operators controlling from opposite ends of a crane or equipment. Tandem Operation This function allows one operator controlling two cranes at the same time via a 3-position A/B/A+B rotary select switch. A special tandem output is provided for external tandem box connection. |

|

|

Random Access Operation This function allows multiple operators randomly controlling multiple cranes on a first come - first served basis. Multiple Receivers Operation This function allows one operator controlling up to ten receivers or equipment at the same time. |

| Worldwide Approvals The Flex ECO systems are fully tested and certified in accordance with the FCC Part-15 Rules and European Safety Standards such as the EN 301 489-1&3, EN 300 220-1&2, EN 60204-32, EN 60950, EN 60529 and EN 13849-1 Category PLd. |

|

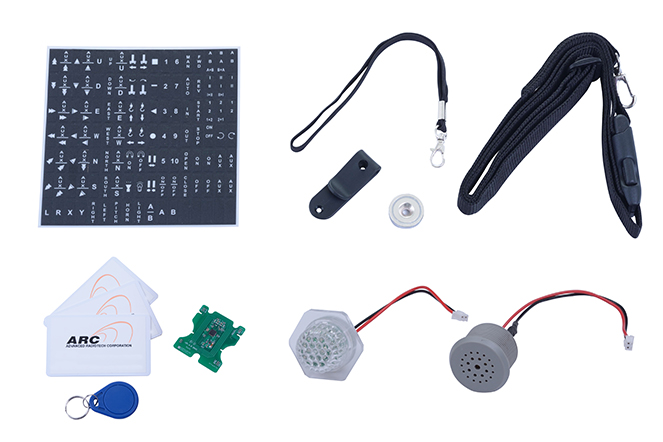

Labels & Accessories |