Flex JX Features

| Transceiving RF modules The Flex JX system is capable of two-way communication between the transmitter and receiver. LCD Readouts All settings and system status information are displayed and executed via the LCD screen on the transmitter and in receiver. Goretex Vent The transmitter is standard-equipped with a Goretex vent to guard against water and vapor buildups inside the transmitter enclosure. |

|

|

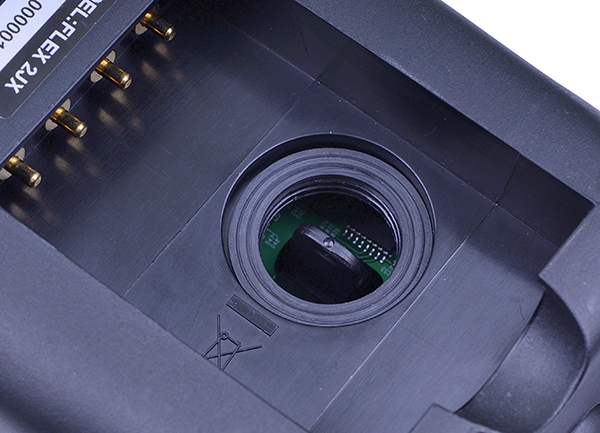

Transmitter Tilt Function The transmitter is embedded with a tilt switch to guard against accidental crane movements when the transmitter is dropped or tilted beyond a certain angle (programmable). Infrared Startup & Range Limiting Functions The transmitter is standard-equipped with infrared sensors for functions such as the infrared system startup and infrared range limiting operations. |

62 User Programmable Channels |

|

|

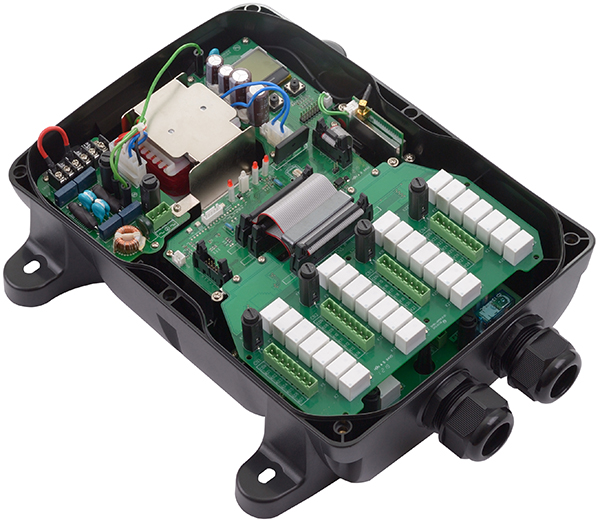

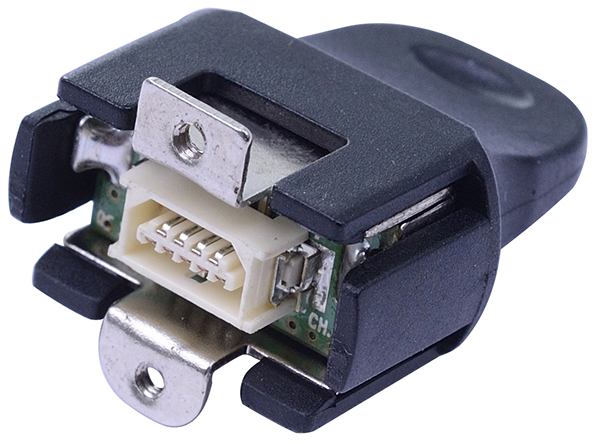

Advanced Controls The Flex JX system utilizes dual advanced microprocessor controls with 32 bit CRC and Hamming Code, providing ultra fast, safe, precise and error-free encoding and decoding. Unique I-CHIP Design The I-CHIP functions similarly to a SIM card. Information and settings can be transferred between transmitters without the hassle of resetting the spares. |

Reliable Joysticks and Levers |

|

|

Low Power Consumption The ultra power-saving transmitter provides more than 30 hours of continuous operation between recharging. Abundant Programmable Functions All functions and settings are easily set via the LCD screens on the transmitter and in receiver, or via the in-house designed programmer unit. Customized functions can also be added upon request. Pitch & Catch Operation This standard-equipped function allows two operators controlling from opposite ends of a crane or equipment. |

Tandem Operation |

|

|

Worldwide Approvals The Flex JX systems are fully tested and certified in accordance with the FCC Part-15 Rules and European Safety Standards such as the EN 301 489-1&3, EN 300 220-1&2, EN 60204-32, EN 60950, EN 60529, EN 60204-32 and EN 13849-1 Category PLd. |